Pebble Time 2

Pebble Time 2

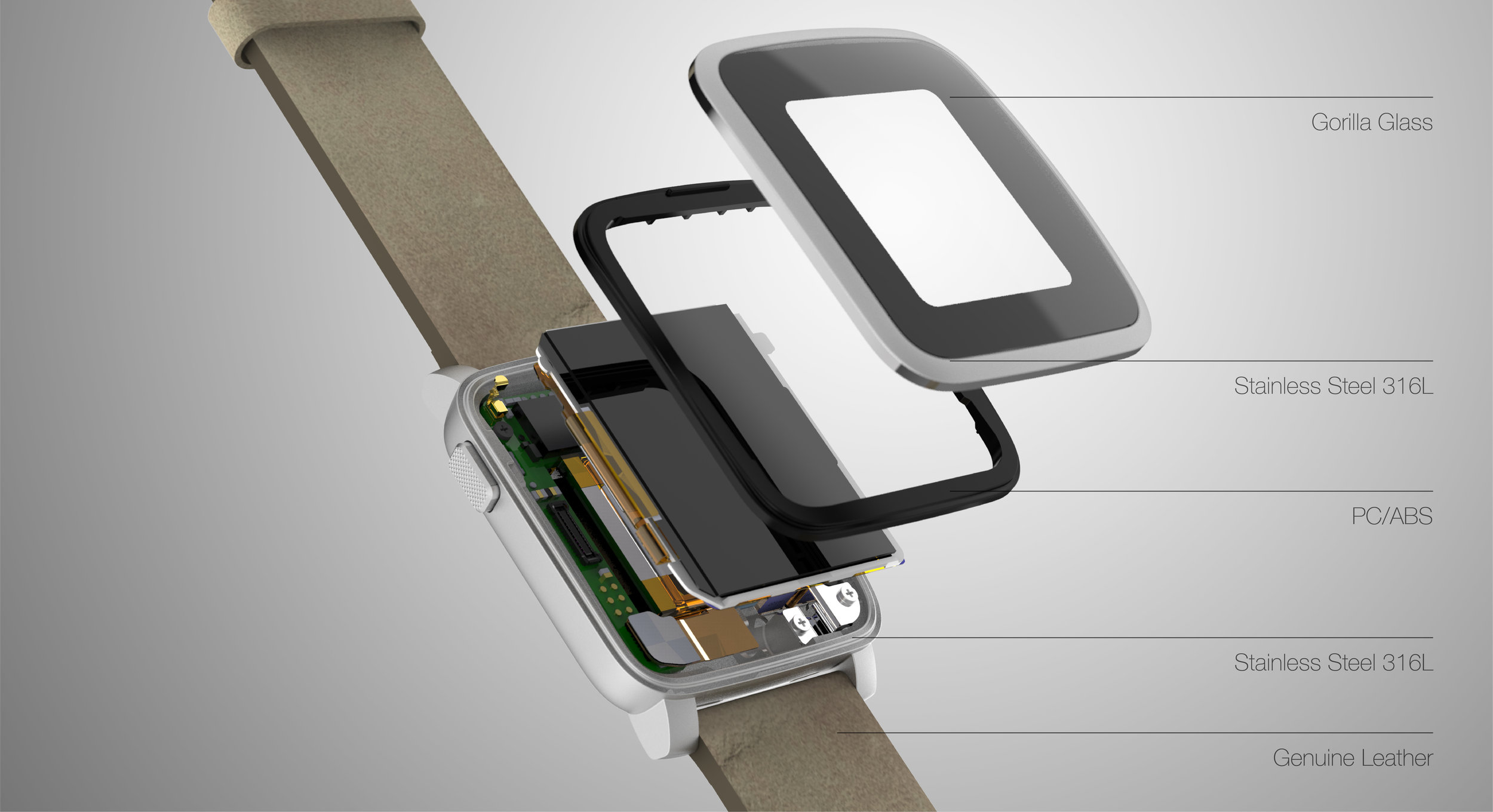

Pebble Time 2 is an evolution of the Pebble Time and Pebble Time Steel devices, meant to show represent our top tier devices while addressing previous pain points. Not only did the design accommodate an all new custom display (a first for Pebble) and a heart rate sensor all while staying the same size, it also became lower cost thanks to detailed material explorations by the design and engineering teams. While creating this product, we made sure to maintain the 3 ATM waterproofing and long battery life that helped Pebble standout in the market.

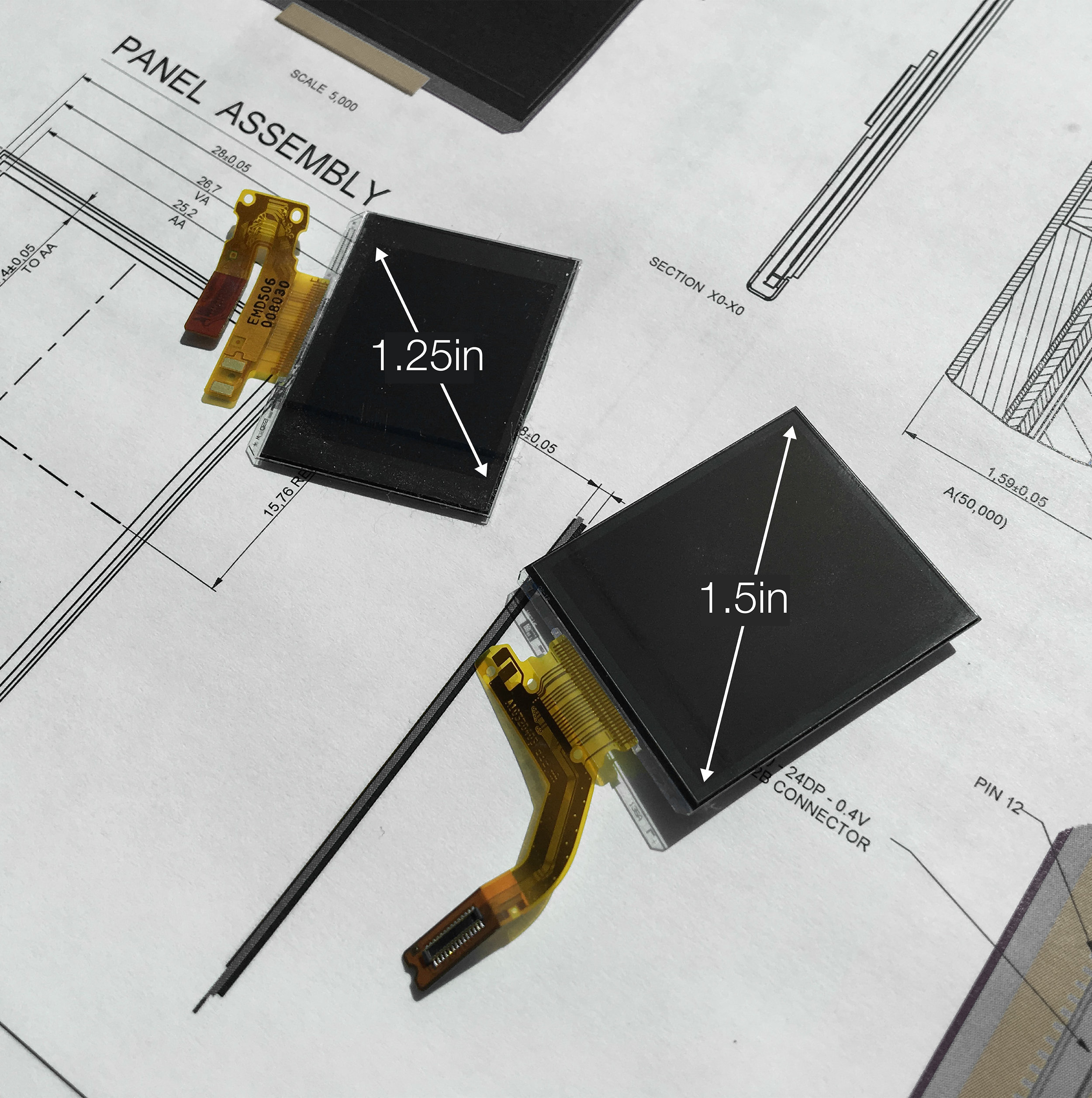

Display

The new custom display had a 50% larger active area with an 80% higher ppi, however the full component was a bit larger as well.

To accommodate the new size, I had to redesign the plastic midframe, resurface the front bezel and glass, as well as change the waterproofing technique entirely.

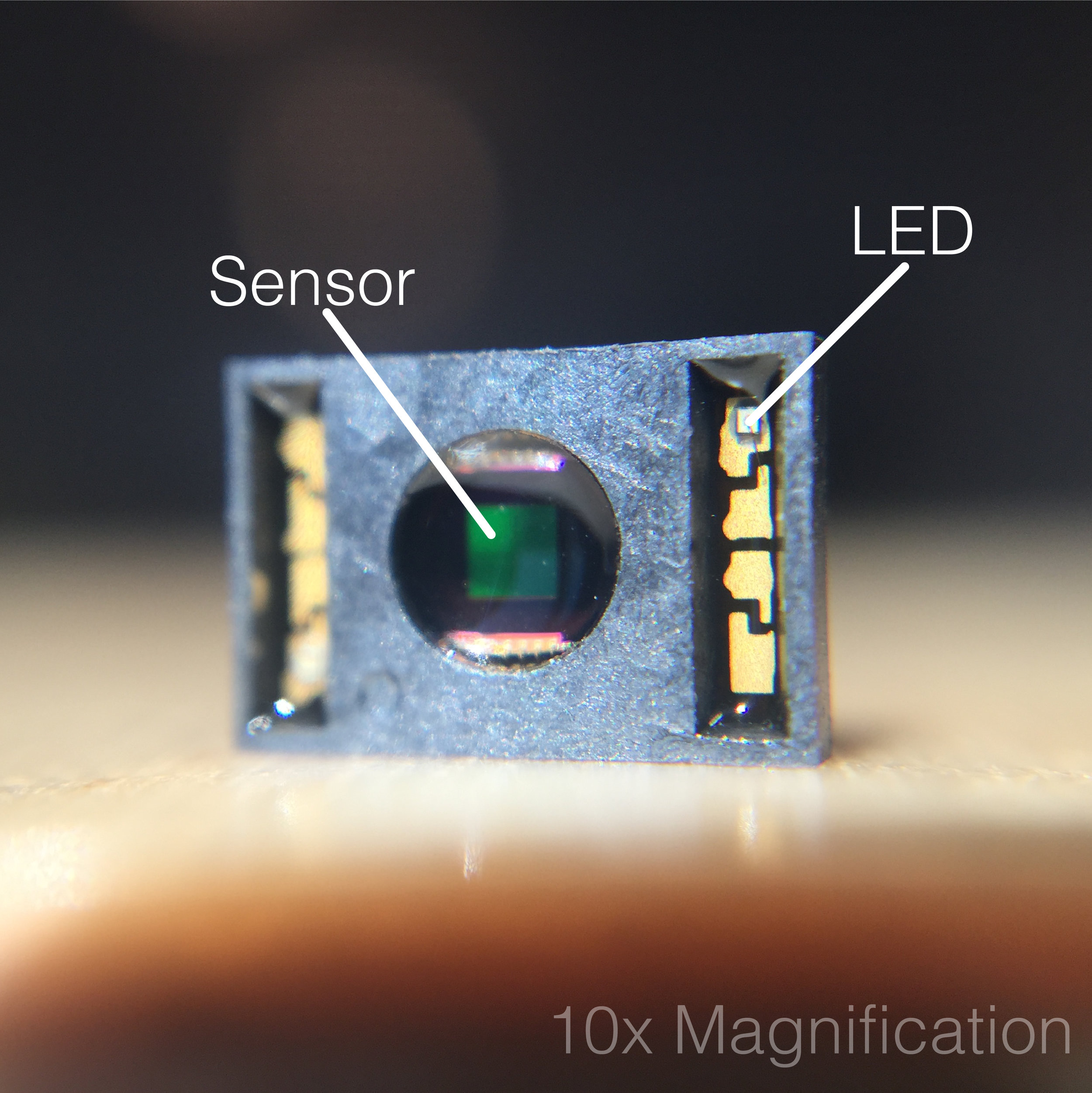

Heartrate

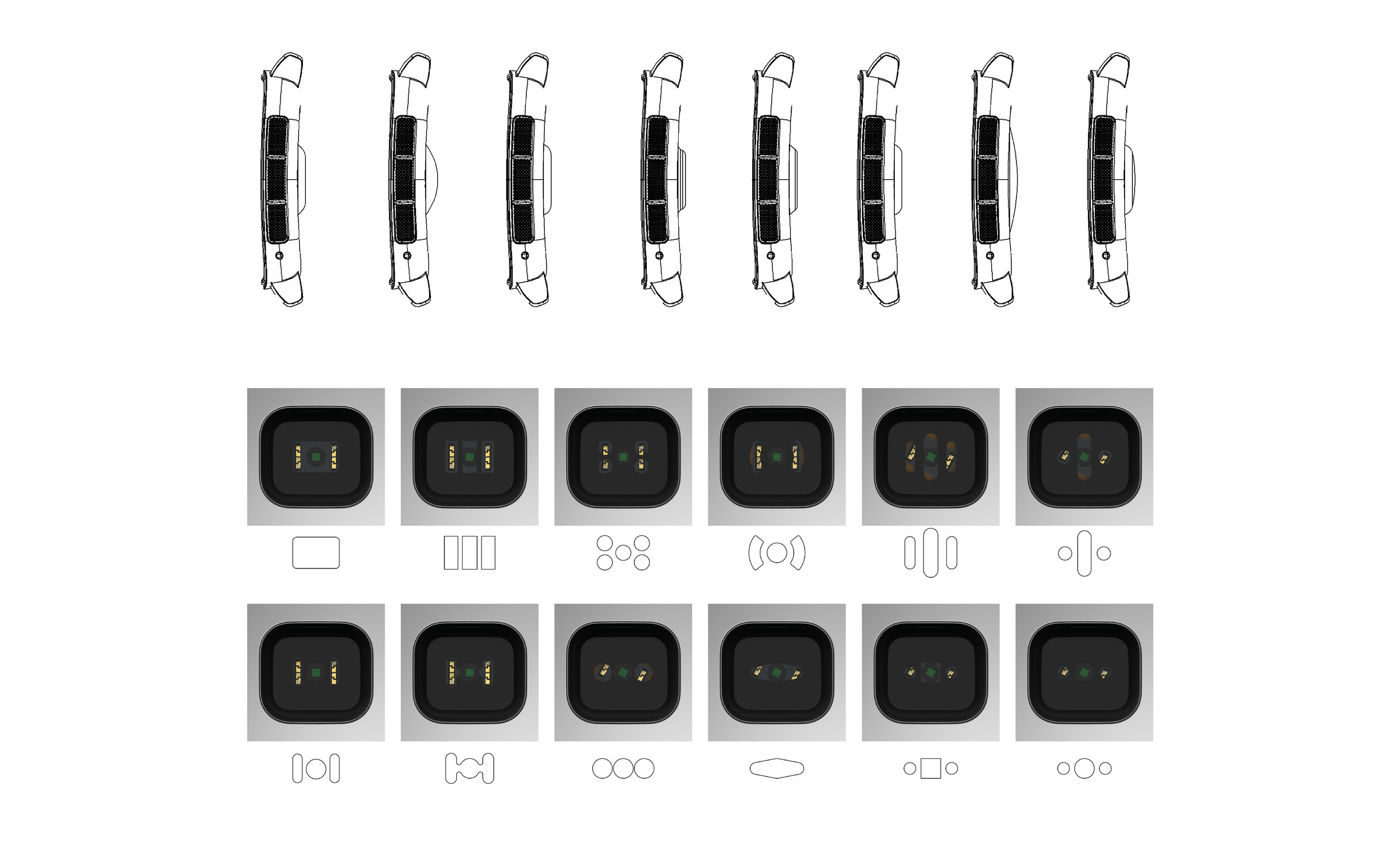

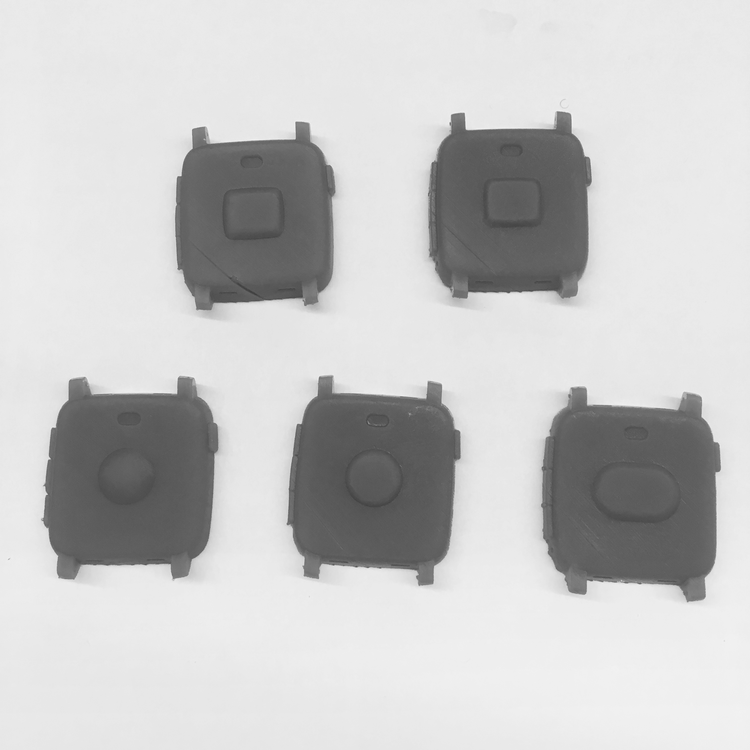

The heartrate sensor chosen was based on the best performance available in an integrated package. We spent time designing an ergonomically and aesthetically pleasing module that maintained peak performance.

Each window design was tested for accuracy under a range of heart-rate conditions , with a range of skin complexions. I personally took part in a every relevant test.

To ensure the comfort of each form, all viable variants were 3D printed and worn for days at a time.

Materials

To make the device more accessible meant lowering the cost for consumer. The most expensive component of the Time Steel was it's housing. Explorations were made around alternate materials as well as lowering the cost of the existing housing.

The final combination of materials allowed us to maintain the quality, aesthetic and performance of the original design while lowering the overall MSRP by 20%.